About Us

You may be aware of the Bluefin Tuna farming activity in Port Lincoln, South Australia. This is a fabulous example of conservation and value enhancement of a limited resource. Originally some 25,000mt (metric tonne) of Bluefin Tuna was caught at a value of aprox $2/kg for canning.

When the resource came to be in danger there was a quota introduced of just 5,000mt nationally and this 5,000mt came to be farmed and fattened to nearly double its weight over 6 months and with an increased value to something like $25/kg for the Japanese sashimi market.

The Australian quota is now 4015 tons per year.

Alongside this is the original cannery which cans the more plentiful but less high grade Skipjack Tuna. This is the only tuna cannery left in Australia.

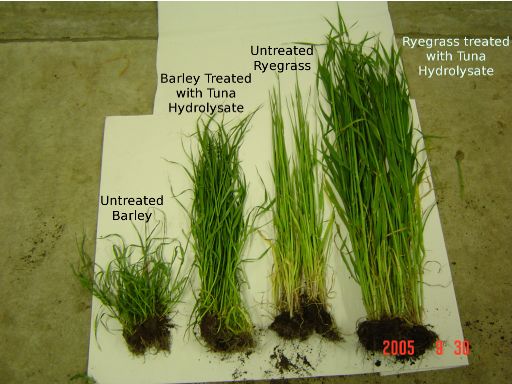

tuna fish hydrolysate treatment.

In both cases there was a problem on the one hand and a dream on the other. The problem was discarding the offal - gills, guts, skins, fins, frames, tails and such. The dream was Charles Franchina's desire to turn about 7,000mt of this offal into a bait for lobster and other trap fisheries both commercial and amateur and so recycling this waste and replacing the large volume of imports.

Peter Laughton shared this dream and was several steps ahead, already processing fish waste in Melbourne, extracting and selling the very rich omega oils to nutritional markets, and testing its potential as a fertiliser, but was lacking finances to expand to Port Lincoln.

Peter Laughton then made the biggest mistake in his life by trusting Charles Franchina and Terry Romaro OAM, and set up a company called SAMPI with equal shares between Peter and Fishtrade. S.A.M.P.I. standing for South Australian Marine Product Industries.

Peter Laughton moved to Port Lincoln and established the processing plant, while Charles Franchina managed all the paperwork in Freemantle.

Charles managed to sell all Sampi product to their own company Fishtrade, and then sold it again to the end user, leaving Sampi with an unknown percentage of the sale price.

Charles and Terry then managed to spend over $AU 1.5 Million of money Sampi did not have, while denying Peter access to any financial records, and ended up putting Sampi into the hands of Administrators on 14 Feb 2011. The final settlement was due on 19 July 2011, and Peter Laughton lost about $100,000 worth of equipment, and no pay for about 5 years of his life. Fishtrade bought all Sampi assets at a bargain price, as no-one else had access to the complete financial records or were able to inspect the assets, and could not see its true worth.

And so now Peter Laughton needs to start afresh, hopefully without the tarnished reputation of the company he built.

Production at the moment is low, as Fishtrade made sure that we could not get some of the equipment we need.

At this point in time it is not economical to get official NASSA certification because the certification cost would only be spread between relatively few produce, but the quality is higher and the benefits still exist for all farmers that do not need NASSA certification.

Click to enlarge ( 572 KB )

While Peter was creating and marketing Sampi's products, agriculture came to understand the importance of soil biology and the negative impact of chemical fertilizers.

The demand for fish hydrolysate (emulsion) grew to a point where the major production was exactly that. The fish contains potassium, nitrogen, phosphorus, selenium and a broad spectrum of other trace elements in plant available form. Fish hydrolysate is in fact a food feeding the essential soil microbes which in turn produce natural essential nutrients which ensure plant health and soil sustainability without chemicals and their negative impact on soil, plant life, the environment and our health.

The oil from the Bluefin is the highest grade tuna oil possible due to the fish itself and the perfect freshness of the raw material. Very high in Omega 3s and, since the process is totally natural with no high heat or chemical treatment there are no odours or unsavoury flavours and is able to be encapsulated or bottled for consumption as a daily therapeutic supplement with wonderful benefits to human health. The Skipjack cannery oil is a lower grade oil used mainly in livestock and aquaculture feed production, petfood, as a berley and many other applications right down to fisholene rust proofing.

Baits were made by adding pollard and alginates to the liquid hydrolysate. Treated like a bread dough, we malax and extrude into baits which were then vacuum packed.

Very effective as a slow release berley, trap and hook bait which does not need to be refrigerated, which is portion controlled, which is long lasting and with high attractant properties as testified by fishermen around Australia.

Since Sampi was stolen, Peter has also been farming worms, and we hope to be able to offer these shortly.

We are hoping to rebuild this stolen dream, and to teach others how to turn their waste product into a valuable asset. Conservation at its best and a lesson to the world to be very careful in whom you trust.

For a detailed look at our history, click here. For a look at the ASIC complaint, Click here.

Landline segment on Sampi before it was stolen.